Your customer ordered your product weeks ago. They’ve been looking forward to it. The box arrives at their door, and in those first 30 seconds of opening it, their entire impression of your brand forms. That moment matters far more than you might think.

Packaging isn’t just cardboard and bubble wrap. It’s often your first physical touchpoint with customers, and it shapes their entire perception of quality, care, and professionalism. When packaging fails, support tickets spike. When it succeeds, customers become advocates.

We understand the frustration: poor packaging leads to damaged products, wrong-item complaints, lost revenue from returns, and frustrated customers flooding your support queue. This guide walks you through the packaging issues that trigger support tickets, how to respond with empathy, and strategies to prevent problems before they start.

Why Packaging Is Your Hidden Customer Service Channel

Packaging speaks louder than marketing copy ever will. It’s the first physical brand experience your customer has, and it sets expectations immediately.

The First Impression Problem

When a customer opens a box, they assess quality in seconds. Professional packaging signals a professional business. Flimsy boxes, loose items, and minimal protection signal carelessness. That impression directly impacts how they rate your product and whether they buy from you again.

This first moment is critical for your customer retention. A positive unboxing experience doesn’t just prevent complaints. It reinforces why they made the purchase and increases the likelihood they’ll buy from you again. Research shows that customers who have positive unboxing experiences are 50% more likely to make a repeat purchase.

Packaging as a Proxy for Product Quality

Customers link packaging quality to product quality. If your packaging looks cheap, they assume the product is cheap, even if it’s exceptional. This perception alone can trigger negative reviews before they even use the product.

74% of consumers consider packaging design in their purchase decisions. That same packaging quality significantly influences whether they’ll shop with you again. Your packaging is inseparable from your product in the customer’s mind.

The Return and Review Trigger

Poor unboxing experiences generate immediate action. Customers don’t sit on their frustration. They return items, leave negative reviews, contact support, and tell others. A single bad unboxing can damage your reputation across multiple channels.

When customers experience packaging failures, they’re three times more likely to post about it on social media or review sites. This amplifies the damage beyond your support queue. One negative review generated from a packaging problem can influence 20 to 30 potential customers.

Hidden Cost of Support Escalation

Every packaging-related ticket costs money. Your support team spends time investigating what went wrong, issuing refunds or replacements, and managing customer anger. That time compounds across hundreds or thousands of orders.

The average eCommerce support ticket costs between 5 and 15 dollars to handle. When packaging failures account for 20 to 30% of your support volume, the financial impact becomes substantial. Better packaging isn’t an expense. It’s a cost reduction strategy.

The Most Common Packaging-Related Support Issues

Understanding what goes wrong helps you fix it. These are the issues we see most frequently driving support volume.

Damaged Products in Transit

The most common complaint: products arrive broken, bent, or unusable. This happens when boxes lack sufficient padding, when materials shift during transport, or when boxes themselves are damaged.

Damage-in-transit is one of the most common packaging-related support issues, with a 2022 study showing that 75% of organizations experienced an increase in lost or damaged packages due to transit issues. The cost of handling these claims, reshipping items, and processing refunds adds up quickly

Support message example: “My item arrived broken. The box wasn’t padded and the item shifted during shipping.”

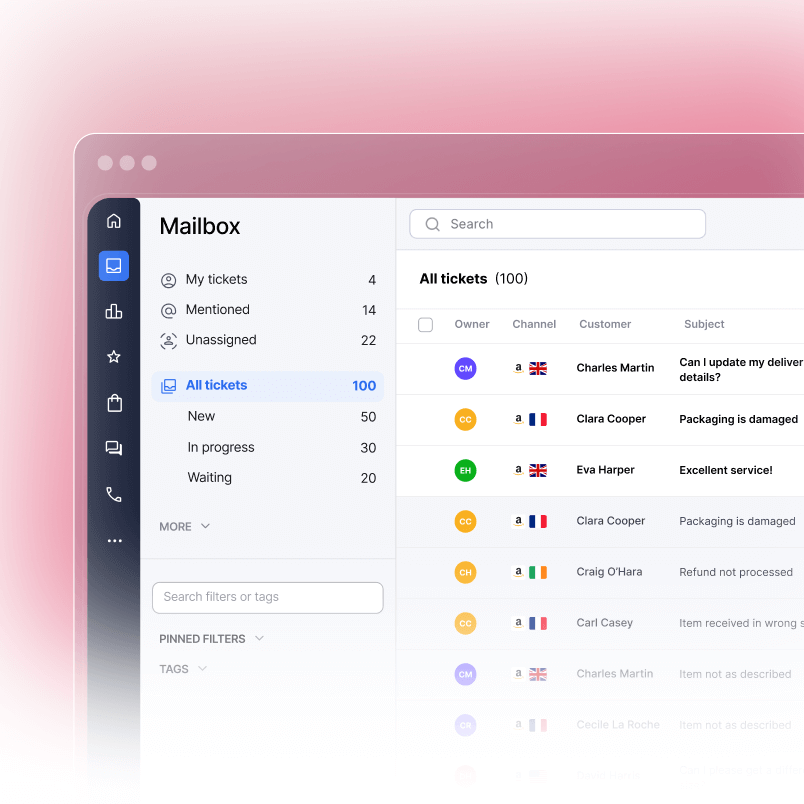

Wrong Item or SKU Confusion

Packing errors create chaos. You send the wrong color, size, or product entirely. These mistakes happen when inner packaging lacks clear labeling, when warehouse staff can’t distinguish between similar SKUs, or when packing stations lack proper visual cues.

Wrong-item errors damage trust immediately. A customer who receives the wrong product doesn’t just want a replacement. They question your attention to detail and your quality standards. These errors are your second-most-common packaging complaint.

Support message example: “I ordered the blue version, but the box contained the red version. The labeling wasn’t clear.”

Excessive Packaging and Waste Concerns

Eco-conscious customers notice and complain about overpackaging. Layers of plastic, unnecessary filler, and branded excess feel wasteful and trigger negative sentiment.

The Nielsen research shows that 62% of consumers globally prioritize brand trust as the top sustainability factor influencing purchasing decisions, but the “expect brands to take action” statistic is actually 81% of global consumers who believe that companies should play a role in improving the environment

Support message example: “This box was huge with tons of plastic. Why so much packaging for such a small item?”

Missing Components or Documentation

Customers receive incomplete orders. Missing instruction manuals, missing return forms, missing safety documentation. These gaps force customers to contact you.

When customers need information they expect to find in the box, they have to track you down. This generates unnecessary support tickets and creates frustration. A simple printed insert prevents hours of support work.

Support message example: “My order arrived but there’s no manual. How do I set this up?”

Underwhelming Presentation and Unmet Expectations

Premium products in cheap packaging create cognitive dissonance. If your product costs $150 but arrives in plain brown cardboard with no protective tissue or thank-you note, customers feel disappointed. Conversely, budget products in over-elaborate packaging also seem dishonest.

Packaging should match product price point and brand positioning. Misalignment creates negative reviews and returns that have nothing to do with product quality.

Support message example: “For the price I paid, I expected better packaging. This feels like a dropped box, not a curated purchase.”

Customer Service Response Scripts for Packaging Complaints

Empathy matters. Here’s how to respond to common packaging issues:

Response to “My Package Arrived Damaged”

Your customer’s frustration is real. They paid for a working product. Address it directly. Don’t make them jump through hoops or prove the damage was your fault.

Script:

“I’m sorry your item arrived damaged. We take this seriously because your satisfaction matters to us. I’m processing a replacement immediately, and you won’t need to return the damaged item. You should receive your new one within five business days. If it doesn’t arrive by [date], reply here and we’ll follow up right away. Thank you for your patience.”

Action steps: Replace without requiring return. Refund shipping. Flag the warehouse or carrier. Track which products or warehouses generate repeat damage complaints.

Response to “There’s Nothing in the Box”

This is alarming for customers. They assume theft or a warehouse error. Stay calm and investigate. Don’t be defensive.

Script:

“I understand how concerning this is. Let me investigate immediately. I’m checking our packing records to see what should have been in your box. Can you reply with a photo of the empty box and the packing slip? Once I confirm the contents on our end, I’ll either reship your item or issue a full refund, your choice. I appreciate you letting us know.”

Action steps: Check packing logs. Investigate for warehouse or carrier issues. Determine if customer received wrong box. Reship or refund same day.

Response to “This Isn’t What I Ordered”

Wrong-item errors damage trust. Acknowledge the mistake without defensiveness. Don’t blame the customer for not being specific enough.

Script:

“You’re absolutely right, and I apologize. Our team made an error packing your order. I’m sending the correct item today at no cost, and you can keep the item we sent by mistake as our apology. You should have your correct item within five business days. Again, I’m sorry for the mix-up.”

Action steps: Ship correct item immediately. Don’t require return of wrong item if cost permits. Flag packing station for retraining.

Response to “Why So Much Plastic?”

Customers who raise waste concerns care about your values. Treat this as a conversation, not a complaint.

Script:

“Thanks for bringing this up. We use protective plastic to ensure your item arrives safely, but I hear you on environmental impact. We’re actively working to reduce packaging waste, and we’re testing compostable materials now. Your feedback influences our decisions on this. If you have suggestions, I’d genuinely like to hear them.”

Action steps: Share your sustainability initiatives. Consider sending a biodegradable packaging info card in future orders. Track feedback by theme.

Packaging Strategies That Reduce Support Volume

Prevention beats response every time. These tactics work.

Tamper-Evident Seals and Packing Checklists

Use tamper-evident tape on boxes. Inside boxes, include a packing checklist. Train warehouse staff to physically check items before sealing and to sign off on each order.

This simple step increases accountability and catches errors before they ship. When warehouse staff know every order is verified, they slow down and stay focused.

Impact: Reduces wrong-item complaints by up to 40%.

Printed Inserts with Contact Info and Clear Returns Policy

Don’t assume customers know your returns policy. Print it. Include your contact info, return instructions, and a QR code linking to your help center.

Many customers won’t go digging through your website to find return information. A simple printed card in the box reduces support inquiries and makes the returns process feel straightforward.

Impact: Reduces support inquiries about returns by 35%.

Clear SKU and Variant Labeling on Inner Packaging

Label the inner box or packaging with the SKU, product name, and variant (size, color, etc.). Color-coded labels for different SKUs prevent packing errors.

When packing stations can visually identify each variant quickly, errors drop dramatically. Your warehouse staff shouldn’t have to squint at a computer screen to figure out what goes in each box.

Impact: Reduces wrong-item errors by 60%.

Visual Unboxing QC Before Fulfillment

Before sealing boxes, photograph the contents. Use AI tools or manual review to verify the right items are in the right box. Spot-check randomly throughout the shift.

This doesn’t require checking every single box. Random spot-checks catch systemic issues and keep staff attentive. One wrong item caught before shipment saves you a refund, return shipping, and support time.

Impact: Catches 95% of packing errors before shipment.

Eco-Friendly Packaging with Explanation Card

Use recyclable or compostable materials. Include a small card explaining your sustainability efforts and how to properly dispose of packaging.

This converts a potential complaint into a brand moment. Customers feel good about supporting a company that shares their values.

Impact: Reduces negative eco-packaging comments by 70%. Increases positive brand sentiment.

Protective Padding That Actually Protects

Invest in quality. Use appropriate padding for product weight and fragility. Cheap bubble wrap and thin cardboard cost more in refunds and replacements than better materials.

The math is straightforward: one replacement order costs far more than premium packaging for 50 orders. Do the calculation for your product category and you’ll see the ROI immediately.

Impact: Reduces damage-in-transit complaints by 50%.

How to Collect and Use Data from Packaging-Related Tickets

Data reveals patterns. Use those patterns to drive decisions.

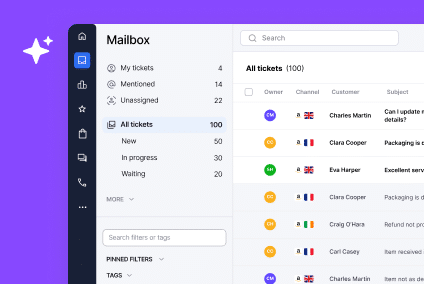

Tag All Packaging-Related Support Tickets

Create consistent tags in your support system: “Packaging Damaged”, “Packaging Wrong Item”, “Packaging Waste”, “Missing Components”, “Packaging Presentation”.

Standardized tags mean you can generate real reports. You need this data to make decisions.

Track Frequency by SKU, Warehouse, or Carrier

Which SKUs generate the most damage complaints? Which warehouse has the highest wrong-item rate? Which carrier loses more packages? Build a monthly report.

This is where decisions get made. You’ll see that one SKU has 10 times more damage complaints than similar products. That’s a signal to investigate that specific product’s packaging. One warehouse has twice the error rate of another. That’s a training or staffing issue.

Correlate Patterns to Action

If one SKU has significantly higher damage complaints, investigate that product. Is it particularly fragile? Is your current packaging appropriate for its weight? Maybe you need custom boxes for that item.

If one warehouse has higher error rates, it’s a staffing or training issue. Address it directly.

If one carrier loses packages consistently, consider alternatives or adjust your packaging for that carrier’s handling.

Share Data with Operations and Design Teams

Don’t hoard this information in support. Report it monthly to operations, fulfillment, and product teams. Make packaging decisions data-driven, not opinion-driven.

The best packaging changes come from collaboration between support, operations, and design. Support sees what breaks. Operations knows what’s possible. Design makes it look good.

Cross-Team Coordination: How Support and Operations Work Together

Packaging decisions shouldn’t live in one department. They require collaboration.

Create a Feedback Loop Between Support and Fulfillment

Your support team sees every complaint. Fulfillment sees every process. Connect them. Weekly or bi-weekly sync calls where support reports top issues and fulfillment discusses workflow changes.

Make these meetings matter. Come with data. Talk about specific tickets and patterns. Discuss potential solutions together.

Include Support in Packaging Decisions

When considering a packaging change, ask support first. They know what breaks, what confuses customers, and what triggers returns. Operations teams would optimize for cost alone. Support knows the human cost of cheap choices.

Support should have a seat at the table when you’re evaluating packaging vendors or testing new materials.

A/B Test Packaging and Measure Impact

Test different packaging approaches on small batches. Measure impact on customer satisfaction, return rates, and support ticket volume. Make decisions based on results, not intuition.

Example: Test premium tissue paper and thank-you cards on one SKU for two weeks. Measure customer satisfaction and repeat purchase rate. If the cost of materials is justified by fewer returns and higher repeat purchases, scale it.

Example: Test reduced plastic packaging with an eco-friendly card. Measure returns, support tickets, and social sentiment. If eco-conscious customers increase repeat purchases, the investment pays for itself.

Document Your Packaging Standards

Create a packaging SOP (standard operating procedure) that defines: box size by product weight, minimum padding requirements, labeling standards, and QC checkpoints. Share it with your warehouse partner or team. Update it quarterly based on ticket data.

When everyone follows the same standards, errors drop and consistency improves. New team members can follow the SOP and deliver quality from day one.

Final Thoughts

Packaging is operations infrastructure that directly impacts customer experience and support costs. A broken box doesn’t just frustrate one customer. It creates a support ticket, risks a negative review, and potentially loses a repeat customer. The math is simple: invest in packaging that prevents problems, and you’ll spend less time managing complaints.

Start here: Pull your last 100 support tickets. Count how many relate to packaging. Calculate the average handling time for each. Multiply by your support cost per hour. That number is your packaging problem’s true cost. Now you can justify investing in better solutions.

Your packaging tells a story about your brand. Make sure it’s the right one. When your packaging works seamlessly with your support processes, customers feel genuinely cared for from the moment they open the box to when they need help. That’s when repeat purchases happen.

Ready to transform your packaging strategy and reduce support volume at the same time? Try eDesk free today to start tracking packaging-related tickets, tagging issues by type, and building a data-driven approach to packaging decisions with your entire team.

FAQs

How does eCommerce packaging affect customer satisfaction?

Packaging is often the first physical touchpoint customers have with your brand. Quality packaging signals professionalism and care, while poor packaging creates immediate negative impressions, drives returns, and generates support tickets. Research shows that 52% of customers factor in packaging quality when deciding to shop with a brand again. Packaging directly impacts repeat purchase likelihood and customer lifetime value.

What’s the most common packaging complaint in eCommerce and DTC?

Damage during transit is the most frequent complaint, followed by wrong-item errors and excessive plastic packaging. Damaged products alone account for roughly 35% of all packaging-related support inquiries. These are preventable issues when proper packaging practices are in place.

How can I reduce support tickets from damaged items in shipping?

Upgrade your padding and box quality based on product weight and fragility. Use properly sized boxes to prevent shifting. Work with your fulfillment partner to implement visual QC checks before sealing. Track which items have the highest damage rate and adjust packaging specifically for those SKUs. Calculate the ROI by comparing replacement costs to packaging upgrade costs.

Should customer service teams be involved in packaging decisions?

Yes. Your support team has frontline visibility into what breaks, what confuses customers, and what triggers complaints. They should contribute to packaging strategy. At minimum, include support in quarterly reviews of packaging performance data. The best packaging solutions come from collaboration between support, operations, and design teams.

Why do customers complain about too much packaging?

Consumers increasingly care about environmental impact. Overpackaging signals waste and creates negative brand sentiment. About 62% of consumers expect brands to take action on environmental issues. Use appropriately sized boxes, minimize plastic, and explain your sustainability approach on an included card. This converts a potential complaint into a brand moment that reinforces your values.

How do I know if my packaging investment is working?

Track packaging-related support ticket volume, categorized by issue type. Monitor return rates, especially for damage-in-transit claims. Measure customer satisfaction scores before and after packaging changes. Calculate the cost savings from reduced support tickets against the packaging upgrade cost. If fewer tickets and higher satisfaction come with a modest packaging cost increase, the ROI is clear and justified.

What’s the relationship between packaging and product quality perception?

Customers link packaging quality to product quality. Poor packaging can make a great product seem mediocre. Premium packaging can elevate a good product. The visual hierarchy of your unboxing experience shapes customer perception before they even use the product. This perception directly influences reviews, repeat purchases, and recommendations.

Can better packaging actually increase repeat purchases?

Yes. Customers who have a positive unboxing experience are more likely to purchase again and more likely to recommend your brand. Premium packaging combined with clear documentation and a thank-you note creates an emotional connection that drives loyalty. The data backs this up. A study of eCommerce unboxing experiences found that customers with positive experiences show 50% higher repeat purchase rates than those with neutral packaging experiences.